At Martin Allen, we’re all about finding our clients the best wood flooring solutions. Whether it’s a small hallway renovation or a large-scale commercial venture, our wood flooring experts and designers treat every project with the utmost care and dedication.

We want our clients to make well-informed and well-thought-out decisions when investing in something as valuable and important as wood flooring. We believe that the only way to do that is to give our clients professional insight into all the wood flooring options they can get at Martin Allen.

Some of our industry’s most frequently asked questions revolve around engineered wood flooring. Although it’s not a new product, it has gained immense popularity recently.

But what is engineered wood, and how is it different from traditional hardwood flooring?

What kind of benefits come with the increased price tag? Is engineered wood the future of timber flooring or another quick fad in interior design?

If you’ve ever wondered about this, continue reading as we answer these and many other similar questions and shed some light on this remarkable material.

What is engineered wood?

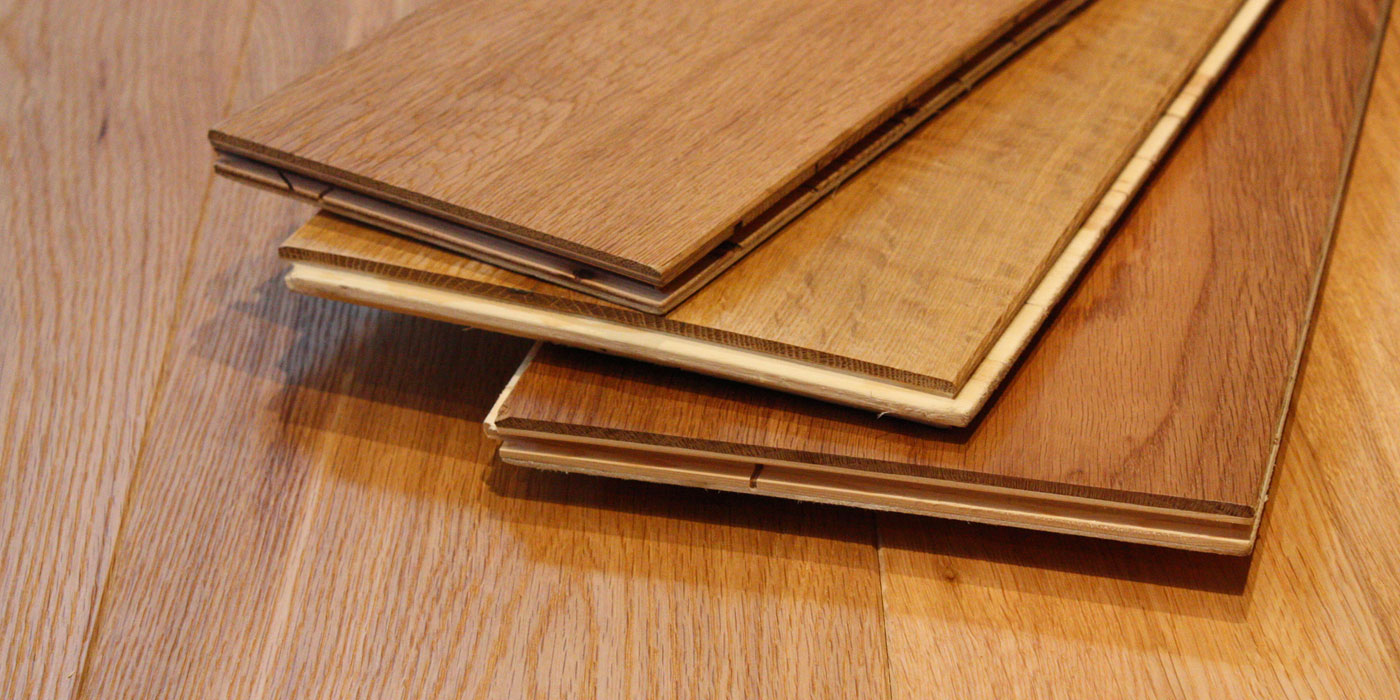

Engineered wood is a composite material of two or more constituent materials with different properties. Unlike laminate and vinyl flooring, engineered wood is made from real, natural wood.

Engineered wood comprises multiple layers, with the wood’s natural grain and colour visible on the topmost layer, the wear layer.

Planks from this composite material have much greater stability and resistance than traditional hardwood planks. This is because every layer of an engineered wood plank is positioned at a 90° angle to the layer above it.

Unlike laminate, which has an image of hardwood printed on top of it, and vinyl, which achieves a wood look by moulding and printing plastic, engineered wood almost entirely consists of solid, hardwood planks.

Except for a few subtypes, such as veneer and acrylic-impregnated flooring, engineered wood floors do not use rotary-peeled veneer, high-density fiberboard, or plastic in their construction.

Benefits of engineered wood flooring

Now that we’ve covered the basics of engineered wood, you might wonder exactly how those things make it better than the more traditional solid wood floors.

There are many benefits, and we’ve tried to cover most of them in the following list.

Durability

The ingenious engineering that went into producing engineered wood makes it much more durable than solid wood.

Layers of wood planks or plywood are stacked together in a perpendicular fashion, which increases the strength of the plank. A strong, sturdy plank can withstand much more foot traffic without experiencing any damage to its surface, making it suitable for both residential and high-influx commercial areas.

While engineered wood and composite wood are interchangeable, the former is most commonly used to refer to indoors, while the latter is used for outdoor wood flooring.

Composite wood can be finished with a UV protectant, making it ideal for use in outdoor decking.

Water and moisture-resistant

As any wood flooring expert will tell you, every type of wood floor is water-resistant if installed correctly.

Want a dark mahogany floor in your bathroom? It’s certainly doable if you’re willing to spend the money.

Engineered wood planks are already water—and moisture-resistant, so there’s no need for additional work after installation. They won’t absorb moisture and thus cannot be structurally damaged by humidity.

Engineered wood floors can also be installed in areas that require water resistance, such as bathrooms, kitchens, washrooms, toilets, etc.

If you are considering bathroom wooden flooring, read our post, Bathroom Wooden Flooring: A No-Go.

Gone are the days of dull ceramic or concrete basement floors because installing engineered hardwood flooring in a cellar is not only doable but also recommended. Engineered wood adds style and luxury to an otherwise underused space, making it look and feel warmer and easier to clean and maintain.

Ability to be refinished

People have always chosen solid wood floors as their preferred “forever” wood flooring solution because they can be sanded and refinished as often as necessary.

While composite materials are much sturdier and durable, they cannot be fixed once their topmost layer is damaged.

However, engineered wood shares many of the properties of solid wood, one of which is the ability to be refinished.

As engineered wood is composed of layers of solid wood, with the plank’s wear layer being the thickest, it can be resanded to remove any surface damage. Although the wear layer can be sanded a limited number of times, it’s still pretty close to how many layers can be stripped from a solid wooden board.

Resanding an engineered wood plank is no different from resanding solid wood, only slightly reducing the thickness of the plank’s top layer. Sanding the wear layer down reveals the wood’s natural grain, revives its colour, and gives it a fresh look.

The sanded plank can then be refinished to your liking. The finish you choose, both in colour and the appearance of the coating, is unlimited.

Considering the imminent threat of surface damage, the need to refinish an engineered wood floor can be a great reason to update your interior design.

Underfloor heating friendly

Heated floors have long been a staple of luxurious interiors. Solid wood floors cannot be installed over underfloor radiant heating, so flooring solutions are limited to a few rather pricey materials.

The engineered wood is perfect for installing underfloor heating systems thanks to its incredible heat resistance.

Engineered wood planks won’t bend, crack, or gap when subjected to constant heat, and they can be fitted even in large, open-space areas without fear of their stability being compromised.

One of engineered wood’s biggest benefits is the ease with which it is installed and dismantled, especially when combined with underfloor radiant heating. As reliable as those systems are, they will eventually need maintenance, which is made easy when dealing with engineered wood flooring.

Complete customisability of the colour and design

One reason people always seem to turn to solid wood is the ability to choose the colour and the finish.

However, as versatile as solid wood can be, nothing beats the number of options engineered wood offers. Customers can choose various finishes, colours, and grain patterns for their engineered planks—and there are a few more options to consider than with traditional solid wood.

The wear layer of an engineered plank is a thin slice of hardwood with visible grain and colour. However, a wear layer requires a significantly thinner cut from the tree’s body than a solid wood plank, making luxurious hardwoods much more affordable.

Have you always wanted your home to breathe with the extravagance of rare, luxurious hardwood floors? With engineered wood planks, you can have exotic wood such as mahogany and walnut at the tip of your toes for just a fraction of the price of solid wood floors.

A wider variety of shapes and sizes

Solid wood flooring can be used and abused to suit even the wildest interior design ideas, but the size of the planks is a wall you’ll eventually hit.

Due to the wood’s tendency to gape and cup, solid wood planks’ maximum width and length are 2100x127mm. Anything larger than that will compromise the floor’s stability and make it prone to cracking and crowning.

While engineered wood planks don’t need to be comprised of a single cut of timber, there’s a much more comprehensive variety of plank sizes.

With the demand for engineered hardwood floors steadily increasing, there are more and more styles to choose from. Engineered wood planks are now specially made to be laid in all kinds of patterns – from classic herringbone and chevron to a more luxurious French and Versailles parquet.

Easy installation

Engineered wood planks are fitted with joints during manufacturing and are installed by interlocking them over a solid surface.

Engineered wood also doesn’t require a specific subfloor to be installed and is usually laid on a floating construction, which keeps them a few centimetres above the original floor level.

Even the floating structure the planks are often installed on requires little construction time.

However, as easy as it sounds, correctly installing engineered wood floors requires expertise that comes with age and experience. The installation process might not take long, but you shouldn’t take it on as a weekend project.

Save yourself the stress of a failed DIY project and contact us at Martin Allen Flooring & French Polishing. A skilled and experienced wood flooring expert will visit you and provide a free on-site quote for wood flooring services.

Sustainability

We’ve seen many clients mistake the term sustainability for the word natural.

Sustainability implies renewability and harmony with nature’s organic processes. Natural means organic and unrefined, which doesn’t always mean sustainable.

Solid wood floors are made by cutting down trees and processing timber to create planks. During the cutting and sawing of timber, a lot of sawdust is produced, which reduces the amount of useful material a single trunk can provide.

Much less solid wood is necessary when it comes to engineered wood planks. The lower layers of the planks can be sourced from less expensive, faster-growing trees, which minimises the lumber industry’s impact on the environment.

The wear layer of engineered boards also doesn’t need to be nearly as thick as that of a solid wood plank. That means the overall amount of useful material that can be extracted from a single timber is much higher, making engineered boards a much better choice for the environment and the budget-conscious.

- By: Andjela Jovetic

- Tags: engineered wood

- Category: Commercial, Home & Domestic, Wood Flooring

- 2 responses comment

Thank you so much for sharing such a nice and very informative post.

Thank you for all of these great examples of the types of flooring to choose for a home!